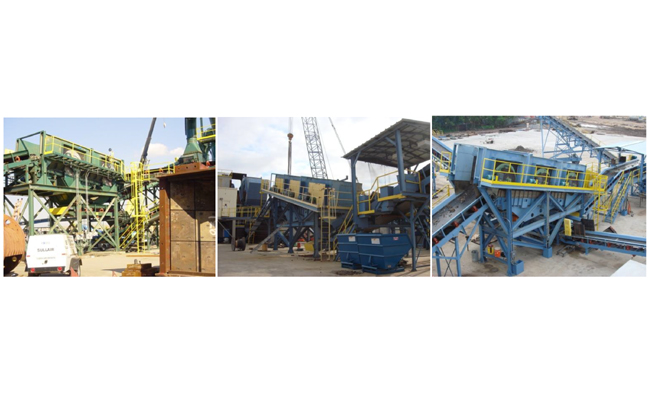

MAGNETIC SEPARATOR

Magnetic Separators are used in the scrap process stream to separate ferrous scrap from all non-magnetic material, called Automobile Scrap Residue (ASR). Generally, the volume split between ferrous and non-ferrous is 50%/50% by volume or 70%/30% by weight. Depending upon required process rate, drum-based Separators are typically designed with one (1), two (2), or three (3) magnetic drums. For multiple drum Separators it is critical that each drum has a high efficiency setup & design, or they will be the cause of excessive tramp ferrous loss in the ASR stream. The use of multiple drum magnets requires installation of Vibratory Feeders, which travel at speeds much slower than belt conveyors but have the advantage of breaking up clumps of entangled material that in turn causes the ASR and ferrous scrap to separate more efficiently.

Hammermills International recommends that the first drum be fed by the upstream conveyor belt at a relatively high speed, using a SS head pulley and horizontal conveyor belt design at the top. This allows for a “rough cut” that produces a good clean ferrous product without major loss of tramp ferrous to the ASR stream.

Technical Design Features:

• Structural Steel Frame w/ Wrap Around Platforms & Stair/Ladder Access

• High Side Skirts, CS and/or SS Construction, Rubber Flap Dampers

• Discharge Chutes with AR 400 Liners

• Shredder Duty, High Strength Drum Magnets. Split Wear Covers

• Adjustable Magnetic Field Angle and High Efficiency Setup & Design

• Electromagnets w/ DC Rectifier in Cabinet

• Gearmotor Drives with Heavy Duty Chain, Sprockets, & Guards

• First Drum can be fed by SS Head Pulley or Vibratory Feeder

• Vibratory Feeder used on Multiple Drum Design. SS Nose on Deck

Options: Adjustable Strength Rectifier, Multiple Drum Designs, Additional Drums Before Picking Stations